Polyether Ether Ketone (PEEK) Market Size to Worth USD 3.91 Bn by 2035

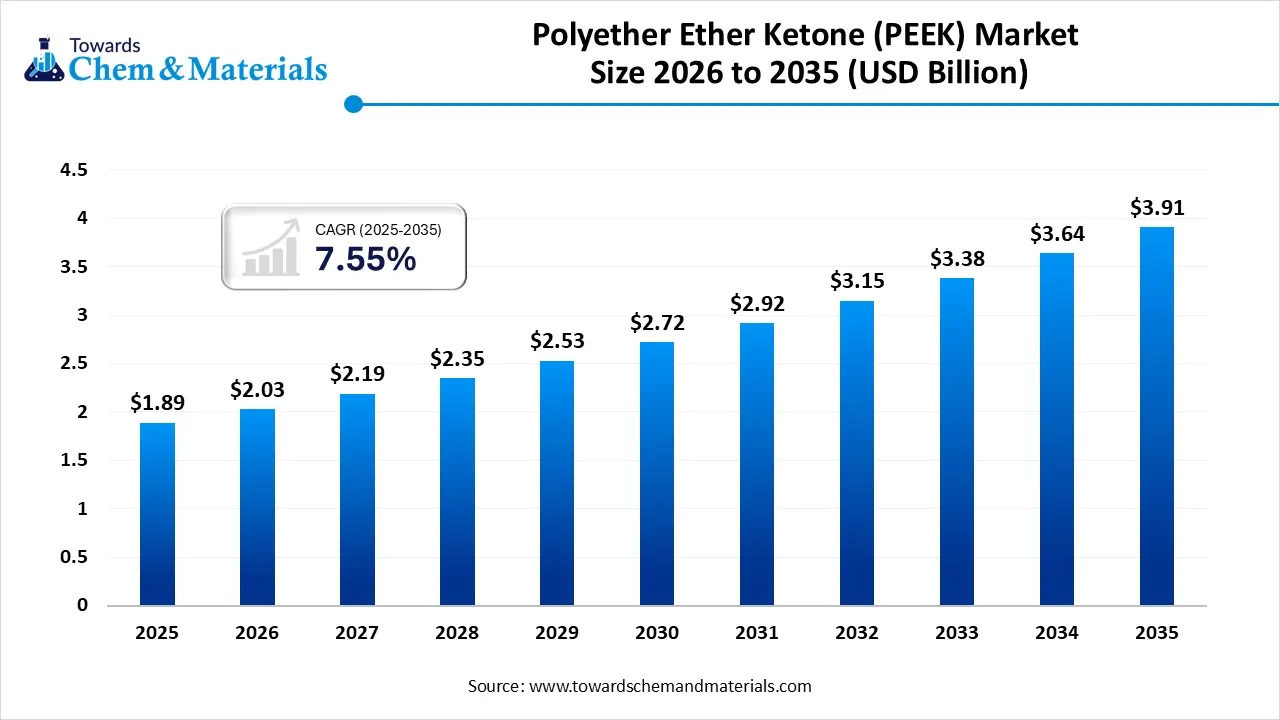

According to Towards Chemical and Materials, the global polyether ether ketone (PEEK) market size was valued at USD 1.89 billion in 2025 and is expected to be worth around USD 3.91 billion by 2035, exhibiting at a compound annual growth rate (CAGR) of 7.55% over the forecast period from 2026 to 2035.

Ottawa, Feb. 11, 2026 (GLOBE NEWSWIRE) -- The global polyether ether ketone (PEEK) market size was estimated at USD 1.89 billion in 2025 and is expected to increase from USD 2.03 billion in 2026 to USD 3.91 billion by 2035, growing at a CAGR of 7.55% from 2026 to 2035. Europe dominated the Polyether ether ketone (PEEK) market with the largest revenue share of 45.11% in 2025. The greater shift towards lightweight materials has fueled the industry's growth in recent years. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5620

PEEK: Powering High Performance Innovation

The polyether ether ketone is primarily known as the higher performance thermoplastic. Also, by having higher heat resistance, stronger mechanical strength, and chemical stability, the polyether ether ketone has allowed stakeholders to capitalize on growth opportunities in recent years, as per the recent industry survey.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Polyether Ether Ketone (PEEK) Market Report Highlights

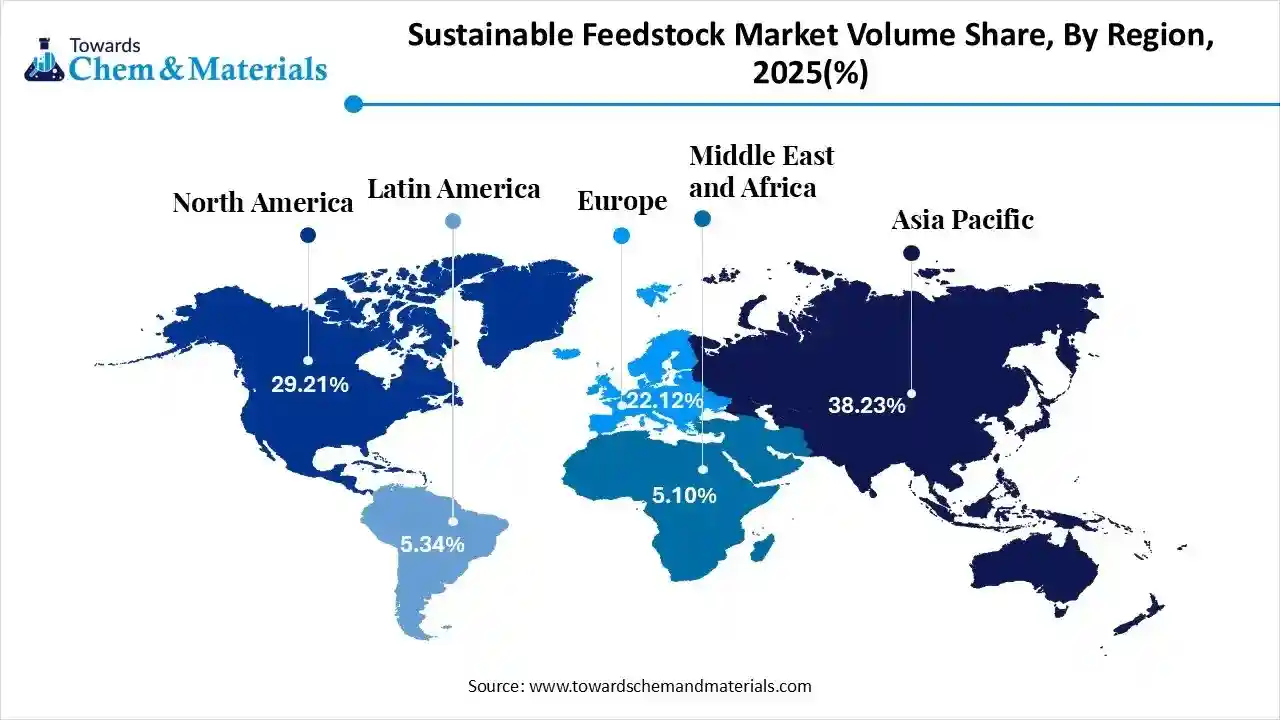

- The Europe dominated the global polyether ether ketone market with the largest volume share of 45.11% in 2025.

- By product, the carbon-filled segment dominated the market and accounted for the largest volume share of 49.18% in 2025.

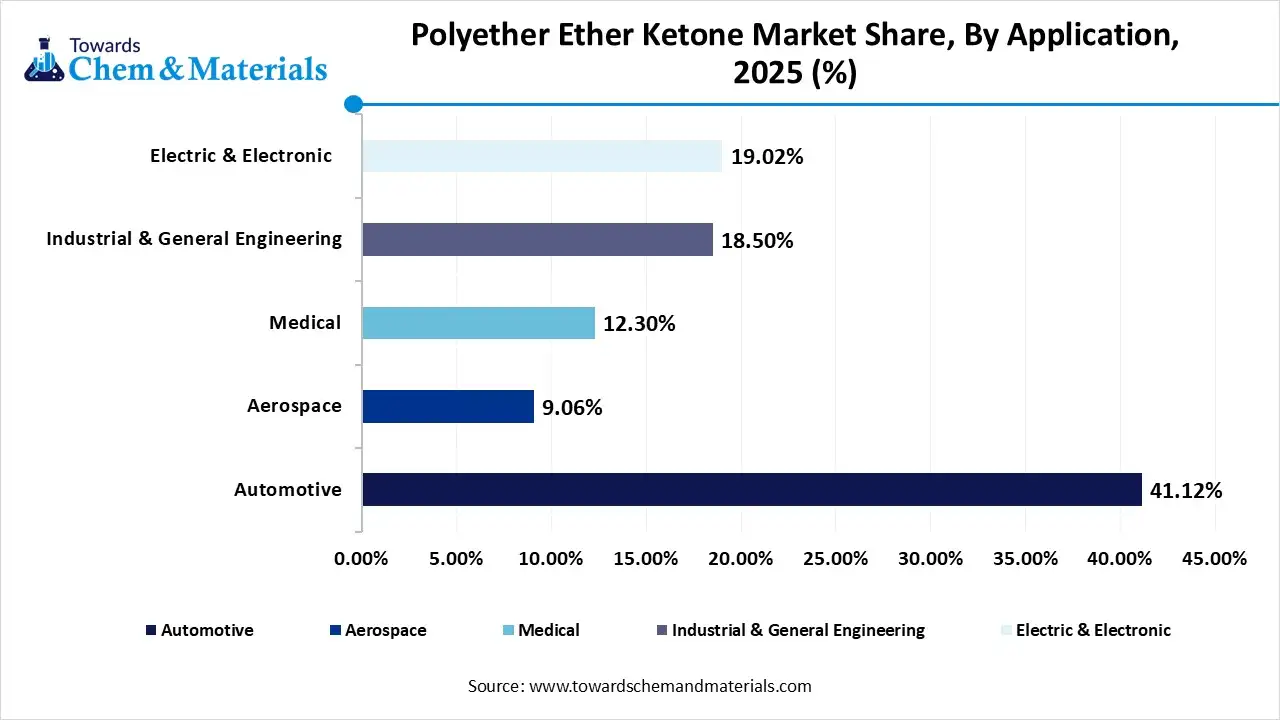

- By application, the automotive segment led the market with the largest revenue volume share of 41.12% in 2025.

What is PEEK (poly-ether-ether-ketone) used for?

PEEK serves critical applications where metals and standard polymers do not meet multiple key engineering requirements. Primary uses include:

- Aerospace: Engine components, structural parts, cable insulation - requires strength, wear, meet smoke, fire, toxicity quality standards, weight-reduction.

- Automotive: Transmission components, thrust washers, seal rings - demands reliability, wear properties, performance in high temperatures, chemical resistance.

- Oil & Gas: Downhole components, seals, bearings - needs chemical resistance, performance under pressure, extreme temperature performance, reliability.

- Medical: Surgical instruments, implantable devices, sterilisation trays - requires biocompatibility, repeated autoclave sterilisation, mechanical performance.

-

Industrial: Chemical processing equipment, semiconductor components, electrical connectors - leverages chemical inertness and dimensional stability.

How much does PEEK cost?

PEEK material pricing reflects its high-performance capabilities:

Material cost considerations:

- PEEK costs significantly more than standard engineering polymers PPS, (nylon, acetal) and alternative metal materials e.g. aluminium, steel, titanium.

- Price varies by grade: unfilled, glass-filled, carbon-filled grades have different costs.

Design efficiency and waste reduction advantages

- Transitioning from metal to PEEK enables component redesign to improve component performance and reduce material usage.

- Metal machining can waste up to 80% of material; injection moulding typically generates less than 5–10% waste.

- PEEK is sold by weight but used by volume in moulding applications.

- Its low density (½ that of aluminium, ⅙ that of steel) means less material is needed for the same part.

- PAEKs are compatible with additive manufacturing, further reducing waste.

Polyether Ether Ketone Market Dynamics

Driver

PEEK Meeting Extreme Performance Demands

The greater need for high-performance materials has increased the commercial viability of the industry in recent years. Moreover, the industries are seeking materials that withstand heat, pressure, and chemicals. PEEK has emerged as the ideal option for these industry participants in the current period, as per the recent industry survey.

Restraint

High-Cost Challenge Peek Adoption

The production cost of PEEK is expected to hinder the industry's potential during the forecast period. Also, PEEK is expensive compared to common plastics. Production requires complex processes and high temperatures. Raw material cost is also high. Small manufacturers avoid PEEK due to budget limits. In cost-sensitive industries, cheaper plastics are preferred. Limited awareness in developing regions slows adoption. Processing PEEK needs special equipment.

Market Opportunity

What is the Most Significant Opportunity for the Polyether Ether Ketone Market?

The increasing demand for electric vehicles and renewable energy is expected to create lucrative opportunities for manufacturers in the coming years. EVs need lightweight and heat-resistant materials. PEEK can be used in battery systems, connectors, and motor parts. Wind and solar equipment also need durable materials. Sustainability goals push innovation. As clean energy expands, advanced polymers are required. PEEK supports efficiency and long service life.

Advanced Processing Transforms Peek Manufacturing

The industry has shifted towards advanced processing and additive manufacturing. 3D printing of PEEK is gaining attention. It allows complex designs and reduced material waste. Improved compounding techniques enhance performance. Automation improves consistency and lowers defects. Recycling methods for high- performance polymers are also being developed.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5620

Polyether Ether Ketone Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 840.2 million |

| Revenue forecast in 2035 | USD 1.33 billion |

| Growth rate | CAGR of 8.0% from 2024 to 2035 |

| Historical data | 2020 - 2025 |

| Forecast period | 2026 - 2035 |

| Quantitative Units | Volume in Tons, Revenue in USD million, and CAGR from 2026 to 2035 |

| Report coverage | Volume forecast, Revenue forecast, competitive landscape, growth factors, and trends |

| Segments covered | Product, application, region |

| Regional scope | North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

| Country scope | U.S.; Canada; Mexico; Germany; UK; France; Italy; Japan; China; India; South Korea; Taiwan; Brazil; Saudi Arabia |

| Key companies profiled | Victrex plc; Caledonian Industries Ltd.; Celanese Corporation; Saudi Basic Industries Corporation (SABIC); Parkway Products, LLC; A. Schulman, Inc. (LyondellBasell Industries Holdings B.V.); J.K. Overseas; Cytec Solvay Group; Evonik Industries AG; Ensinger GmbH |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Key Applications of Polyether Ether Ketone:

- Medical Implants: PEEK is used for spinal fusion cages and orthopedic pins because its modulus of elasticity is similar to human bone, and it is fully biocompatible.

- Aerospace Components: It replaces metals in engine parts and brackets to reduce aircraft weight while maintaining resistance to high temperatures and harsh chemicals.

- Automotive Systems: The material is used in transmission components and seal rings due to its exceptional wear resistance and ability to operate in hot, oily environments.

- Oil and Gas Equipment: PEEK is ideal for downhole seals and valves because it remains stable under extreme pressure and exposure to corrosive hydrocarbons.

- Electronics Engineering: It serves as high-performance insulation for cables and connectors because it maintains excellent dielectric properties even at high voltages.

- Dental Prosthetics: In dentistry, PEEK is utilized for bridges and denture frameworks because it is lightweight, non-metallic, and easy to mill into precise shapes.

What are the Major Trends in the Polyether Ether Ketone Market?

- Increasing Need for Medical Implants: The increasing need for medical implants in the developing and developed regions has driven the strategic transformation and sectoral scalability in recent years. As it is used in dental devices, spinal implants, and orthopaedic parts.

- Lighter and Corrosion-Free Materials: Increasing demand for lighter and corrosion-free materials in the manufacturing industry has opened profitable avenues for PEEK manufacturers. As the industry is seen as replacing metal parts with PEEK installations.

- Electronics and Semiconductors: Increasing demand for electronics and semiconductors has actively created profitable pathways for sector participants in recent years. By having the capability to handle high heat and electrical insulation needs, PEEK has gained an industry advantage in recent years.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5620

Polyether Ether Ketone (PEEK) Market Segmentation Insights

Segmental Insights

Product Insights

Why did the Carbon Filled Segment Hold the Biggest Share in the Polyether Ether Ketone Market?

The carbon-filled segment dominates the market, owing to its offering of very high strength and stiffness. Industries use it where parts face heavy loads, heat, and wear. Carbon-filled improves mechanical performance and reduces friction. Automotive, industrial machinery, and electronics need durable materials. Carbon-filled PEEK also performs well in moving parts like gears and bearings.

The glass-filled segment is experiencing the fastest growth in the market during the projected period, due to industries wanting balanced performance at lower cost. Glass filling improves stiffness and dimensional stability while being cheaper than carbon filling. Many applications do not need extreme strength. Electronics, appliances, and general engineering parts prefer cost-efficient materials. Glass-filled PEEK works well for structural parts and housing.

Application Type Insights

How Did the Automotive Segment Dominate the Polyether Ether Ketone Market?

The automotive segment dominates due to car manufacturers adopting lightweight materials early. PEEK helps reduce vehicle weight and improve fuel efficiency. It is used in gears, seals, connectors, and under-hood parts. PEEK handles heat, vibration, and chemicals well. Automotive production volumes are very high. Even small material usage creates great demand.

The aerospace segment is anticipated to grow fastest during the projected period, owing to aircraft requiring extreme performance materials. PEEK is lightweight, strong, and heat-resistant. It helps reduce aircraft weight, improving fuel efficiency. Aerospace standards are very strict, and PEEK meets them well use of PEEK in structural parts, cable insulation, and interior components is increasing. Aircraft production is rising globally.

Regional Insights

How did Europe hold the Largest Share of the Polyether Ether Ketone Market?

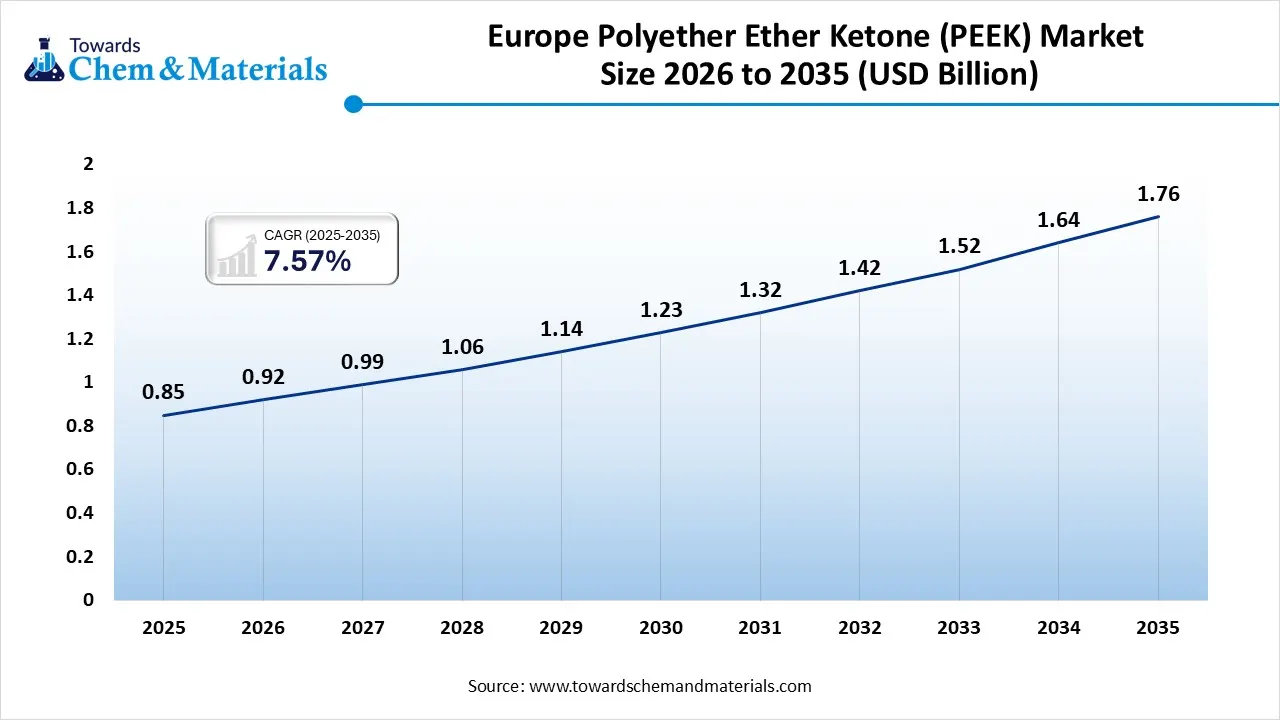

The Europe polyether ether ketone market size was valued at USD 0.85 billion in 2025 and is expected to be worth around USD 1.76 billion by 2035, exhibiting at a compound annual growth rate (CAGR) of 7.57% over the forecast period from 2026 to 2035.

The Europe region leads the global polyether ether ketone market due to the greater focus on precision and high-performance materials. Moreover, the major industries in the region, such as the automotive, aerospace, and medical industries, have seen a higher demand for reliable polymers, which is likely to create greater advantages for PEEK in the coming years, as per the recent regional observation.

Germany Polyether Ether Ketone Market Trends

Germany’s market is growing steadily as the country's strong automotive, aerospace, and industrial machinery sectors increase demand for high-performance polymers that offer lightweight strength and heat resistance. German manufacturers are integrating PEEK into electric vehicle components and advanced engineering parts to support sustainability and efficiency goals.

Central & South America Polyether Ether Ketone (PEEK) Market Trends

The Central & South America PEEK market is progressing at a significant growth rate owing to the ongoing developments in the electronics and automotive industries. The electronics industry is attracting global investors owing to industrial development across vertical markets, and economic growth in the region.

Middle East & Africa Polyether Ether Ketone (PEEK) Market Trends

The PEEK market in MEA has rebounded in recent years. The region is projected to continue to witness positive growth in the PEEK demand with the lifting of economic sanctions in Iran and the drive for economic diversification between the oil-exporting countries of the Gulf Cooperation Council.

Why is the Polyether Ether Ketone Market Growing Rapidly in North America?

The Asia Pacific region is the fastest-growing region, akin to rapid industrial growth and manufacturing expansion. The regional countries such as China, Japan, and South Korea are increasing production of electronics, electric vehicles, and medical devices. Demand for lightweight and heat-resistant materials is rising. Asia Pacific focuses on cost reduction and large-scale production, making PEEK more affordable.

China Polyether Ether Ketone Market Trends

China’s market is experiencing robust growth driven by rapid industrialization and strong demand from key sectors like automotive, electronics, and aerospace, where high-performance materials are increasingly required. Domestic production and capacity expansion have boosted supply, although China still imports high-end grades while exporting mid-tier PEEK to neighboring markets.

U.S. Polyether Ether Ketone (PEEK) Market Trends

The PEEK Market in the U.S. held the largest share in the region in 2025. The U.S. enjoys several advantages in the evolving flexible electronics technology field. The country has the best and largest research universities across the globe, most of which are engaged in research & development projects related to the development of flexible electronics in the U.S.

More Insights in Towards Chemical and Materials:

- Polyethylene Terephthalate Catalyst Market Size to Hit USD 1,321.75 Mn by 2034

- U.S. Recycled Polyethylene Terephthalate Market Size to Reach USD 7.53 Bn by 2034

- Linear Low-Density Polyethylene (LLDPE) Market Size to Reach USD 118.69 Bn by 2034

- Polyethylene Terephthalate (PET) Market Size to Reach USD 68 Bn by 2034

- Polyethylene Glycol (PEG) Market Volume to Exceed 788,565.1 Tons by 2034

- Polyethylene Wax Market Size to Reach USD 3.56 Bn By 2034

- Mechanical & Chemical Recycling of Polyethylene Market Size, Share | CAGR of 10.29%

- Low-Density Polyethylene (LDPE) Market Size to Reach USD 80.34 Billion by 2034

- Polyethylene Market Size to Surpass USD 268.36 Billion 2035

- Aerospace Plastics Market Size to Worth Around USD 23.28 Bn by 2035

- Aerospace Materials Market Size to Reach USD 112.78 Bn by 2035

- Aerospace Adhesives and Sealants Market Size to Hit USD 3.66 Bn by 2035

- Aerospace and Defense Materials Market Size to Surpass USD 49.07 Bn by 2035

- Aerospace Foam Market Size to Exceed USD 13.27 Billion by 2034

- U.S. Aerospace Foam Market Size to Reach USD 6.22 Billion by 2034

- PAN-based Carbon Fiber Market Size to Hit USD 10.16 Bn by 2035

- Standard Modulus Carbon Fiber Market Size to Hit USD 7.56 Bn by 2035

- Propylene Carbonate Market Size to Hit USD 782.56 Million by 2035

- Chemical Decarbonization Market Size to Surpass USD 665.56 Bn by 2035

- Carbon Capture Utilization Chemicals Market Size to Hit USD 527.01 Bn by 2035

- Advanced Carbon Materials Market Size to Hit USD 86.27 Bn by 2035

- Low-Carbon Construction Material Market Size to Hit USD 601.63 Bn by 2034

- Carbon Black Market Size to Surpass USD 44.77 Billion by 2034

- Carbon Fiber Reinforced Plastic (CFRP) Market Size to Surge USD 48.08 Bn by 2034

- Carbon Steel Market Size to Surpass USD 1,802.47 Billion by 2035

- Bio-based Polycarbonate Market Size to Reach USD 182.5 million by 2034

- Specialty Carbon Black Market Size to Reach USD 8.54 Billion by 2034

- Sodium Carbonate Market Size to Hit USD 16.84 Billion by 2034

- Carbon Dioxide Removal Market Size to Reach USD 2,864.36 Million by 2034

- Carbon Disulfide Market Size to Reach Around USD 215.64 million by 2034

-

Polyethylene Furanoate (PEF) Market Size to Hit USD 3,233.78 Mn by 2035

Top Companies in the Polyether Ether Ketone Market & Their Offerings:

- Victrex plc: A global market leader that manufactures high-performance PEEK resins, powders, and specialty forms like Victrex PEEK films and composite tapes.

- Evonik Industries AG: Produces high-performance VESTAKEEP® PEEK resins and compounds specifically engineered for extreme thermal and chemical environments.

- Ensinger GmbH: Specializes in the conversion of PEEK into semi-finished shapes, such as TECAPEEK rods, plates, and tubes, and precision-machined parts.

- Saudi Basic Industries Corporation (SABIC): Offers high-heat LNP™ compounds and specialty resins that compete in the high-performance polyether ketone space.

- Celanese Corporation: Supplies industrial-grade PEEK through its high-performance polymer portfolio, focusing on grades with optimized flow for complex injection molding.

- Cytec Solvay Group: Provides specialized PAEK and PEEK materials, particularly KetaSpire® PEEK, tailored for the rigorous demands of aerospace and oil and gas.

- A. Schulman, Inc. (LyondellBasell): Now part of LyondellBasell, they provide customized PEEK compounds and masterbatches for specific industrial color and performance requirements.

- Parkway Products, LLC: A precision manufacturer offering custom injection molding and magnesium thixomolding of PEEK for aerospace and medical OEMs.

- Caledonian Industries Ltd.: Acts as a specialist manufacturer and converter, providing PEEK-based thermal and electrical insulation components for harsh environments.

- J. K. Overseas: Operates as a prominent supplier and distributor of semi-finished PEEK products, including rods and sheets for general engineering use.

Polyether Ether Ketone (PEEK) Market Top Key Companies:

- Victrex plc

- Caledonian Industries Ltd.

- Celanese Corporation

- Saudi Basic Industries Corporation (SABIC)

- Parkway Products, LLC

- A. Schulman, Inc. (LyondellBasell Industries Holdings B.V.)

- J.K. Overseas

- Cytec Solvay Group

- Evonik Industries AG

- Ensinger GmbH

Recent Developments

- In August 2025, researchers from the Astana IT University conducted a study showing that CoCr-filled PEEK can deliver markedly improved hardness and wear resistance while retaining thermal properties and frictional behavior comparable to neat PEEK, making these composites strong candidates for high-load, wear-critical applications

- In July 2025, scientists from the Dalian Maritime University conducted research utilizing material extrusion additive manufacturing technology to fabricate polyether-ether-ketone (PEEK) based on triply periodic minimal surface (Gyroid) structures and three-dimensional plate-like lattice structures (BCC and FCC).

-

In September 2025, Essentra introduced its latest range of PEEK fasteners. Also, these newly launched PEEKs have greater thermal stability, exceptional chemical resistance, and mechanical properties as per the company's claim.

Polyether Ether Ketone (PEEK) Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2035. For this study, Towards Chemical and Materials has segmented the global Polyether Ether Ketone (PEEK) Market

By Product

- Carbon Filled

- Glass Filled

- Unfilled

By Application

- Automotive

- Aerospace

- Medical

- Industrial & General Engineering

- Electric & Electronic

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5620

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics | TCM Blog

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.